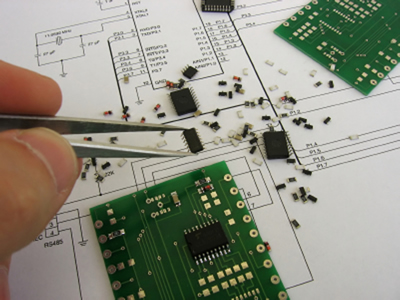

Introduction To PCB Assembly

PCB or printed circuit board is one of the most important concepts in the world of electronics. The circuit boards are required to go through a PCB assembly process in which a selective soldering machine plays an integral role. Read this post to know the basics of PCB assembly and how it is used to create PCB’s-

PCB assembly or PCBA is a process in which electric components are soldered or assembled on a printed circuit board. Before the assembly of electronic components, circuit boards are known as PCB’s. When the components are soldered on to them, the boards are then known as PCA (Printed Circuit Assembly) of PCBA (Printed Circuit Board Assembly).

It is important to note that manufacturing of circuit boards is completely different from assembling a circuit board. Manufacturing of these boards require a variety of processes like designing of PCB and creating prototypes of PCB. When a board is manufactured, it then goes through the assembly process in which electrical components are soldered onto it before it can be installed in any electronic gadget, machine or equipment. Assembly of the electronic components relies on a number of factors, like the type of board, the purpose of the board, etc.

Things Required for PCB Assembly-

-

PCB

-

Electronic components to be soldered on the board

-

Soldering materials like Soldering flux, paste, wire, bar and preforms

-

Soldering machine (Selective soldering machine is very commonly used for the assembly)

-

Soldering flux

Once all the raw materials, electronic parts, and equipment are arranged, the assembly process can begin. The printed boards are generally of two different types- ones that have thru-hole components and others that do not have such components.

Thru-Hole Components

The components that feature leads inserted through small holes in the board are known as thru-hole components. The soldering process or assembly requires hand soldering and wave soldering. In wave soldering assembly, solder bars are put in elevated temperature bath for soldering. The solder remains in molten form at the elevated temperature and results in the creation of wave.

Traditional hand soldering or tin/lead soldering has low melting temperature as compared to wave soldering. A board with thru-hole components is passed through molten solder by a conveyor belt. When the components are soldered, the board is cleaned and is required to go through testing. If the board has any faults, it is then sent for reworking which usually involves hand soldering.

Non-Thru Hole Components

SMT (Surface Mount Technology) is used for PCB assembly of boards without through-hole components. These components are directly on the circuit boards surface. The electronic components, equipment and soldering materials used for SMT are different from the ones used for soldering thru-hole components.

With falling Soldering machine price, PCB assemblers shpcb-assemblyould surely invest in a modern selective soldering machine to accelerate the soldering process and get a better outcome. However, make sure that you choose a reputable seller for buying a soldering machine to make sure that the purchase effortlessly satisfies your expectations.